18 ways supply chain digital twins streamline logistics

[ad_1]

We are excited to bring Transform 2022 back in-person July 19 and virtually July 20 – 28. Join AI and data leaders for insightful talks and exciting networking opportunities. Register today!

Digital twins have become increasingly invaluable for enterprises to improve their supply chain planning. Whereas many digital twins simulate products or buildings, supply chain twins model the diffuse connections between raw materials, finished products and customers. Supply chain twins are growing in importance as enterprises try to keep pace with disruptions caused by COVID-19, shipping bottlenecks and sanctions.

“The major disruptions over the past couple of years have made supply chain predictability and resiliency top priorities for businesses,” Brian Bronson, president of Americas and APAC at Capgemini Engineering, told VentureBeat. “A company’s supply chain has many steps and moving parts along the entire work stream and with each one comes another variable where more potential challenges could arise.”

Digital twins can help anticipate these scenarios and develop alternate strategies to meet customer expectations at minimal cost. Enterprises can recreate everything from shipping to trucking and other means of transport, inventory within warehouses and distribution centers and the last-mile delivery of products to their destinations.

Harpreet Gulati, senior VP for planning, simulation and optimization business at Aveva, said, “Digital twin technology is the future of supply chain management and one of the biggest advantages is that no matter where people are, they see the same picture,” said Harpreet Gulati, senior VP for planning, simulation and optimization business at Aveva. Supply chain twins can also enable collaboration across planning, scheduling, operations and distribution and ensure everyone has the same understanding of a plant and business.

Here are 18 ways digital twins are being used to streamline supply chain logistics:

Strategic planning

Enterprises used to develop a strategic plan once per year using tons of spreadsheets. Digital twins bring all the data together, allowing teams to revise these short to medium-term plans multiple times per year. “A supply chain digital twin can be used for strategic planning as it can assimilate historical enterprise, environmental, geospatial, structured and unstructured data,” NTT supply chain transformation lead Yogesh Amraotkar told VentureBeat. A supply chain twin can predict potential hazards and simulate various options to overcome them.

Operational planning

Operational planning helps calibrate procurement and shipping activities a few weeks to a few months out. This considers factors like the ocean liners carrying goods for the next season and parts and raw materials for cars, trucks or industrial equipment scheduled to be manufactured over the next quarter. Operational planning can help teams map the tradeoffs between faster routes via planes and more cost-effective routes via ships. Digital twins can also help enterprises keep abreast of new bottlenecks at ports and other routes to plan cost-effective alternatives, Amraotkar said.

Tactical coordination

“Supply chain digital twins can equally shine by mitigating risks almost in real-time,” Amraotkar said. Tactical planning helps mitigate the impact of unplanned events leading to disruptions in one link that affect multiple components across the entire value chain. However, this use of digital twins requires more buy-in among front-line workers that might be involved in implementing the changes. He cautions that without coordinated efforts to orchestrate the outcomes of a digital twin, different stakeholders may take decisions they think would mitigate an impending situation. In isolation, each would be right but counterproductive if those decisions do not align in the same direction. Digital twins could help bring decision-makers together to evaluate the results of the simulations to reach a collective decision.

Optimize sales and operations alignment

“A digital twin, which includes various supply and demand inputs and other components of the supply chain network, including warehouses, logistics and inventory levels, is an essential tool for the sales and operations teams,” Owen Keates, industry executive at Hitachi Vantara, told VentureBeat.

A typical supply chain team presents a monthly recommended sales and operations plan to the executive team for consideration and sign-off. This plan connects sales orders and forecasts with the capacity of the business to manufacture and procure the required goods to meet demand. Consideration is also given to risk value, the confidence levels of the demand plans and other potential disruptions such as factory maintenance shutdowns or delays in procurement. Digital twins could help teams run “what-if” scenarios” to assess the various risk profiles and the optimum balancing of demand with the ability to supply.

Chaos engineering for supply chains

Companies like Netflix have demonstrated the value of chaos engineering for applying shocks to software infrastructure to build more resilient systems. Digital twins allow enterprises to perform the same testing and analysis with supply chains. David Shillingford, chief strategy officer at Everstream Analytics, told VentureBeat that enterprises use supply chain twins for scenario planning where “shocks” are applied to different parts of the network to assess the impact and optimal responses. Connecting this layer to live data helps teams connect with event monitoring to understand the implications of new developments. This “risk-adjusted” digital twin can also assess network, lane and shipment risk by ingesting shipment plans and transportation data. This allows companies to take risk into account in almost every decision, from product design to final delivery.

Optimize warehouse space

The shortage of commercial warehouses and industrial space is another result of the ongoing supply chain crisis. “The best way to maximize existing space is by optimizing the facility’s perimeter, which can be done using digital twins of loading docks and yards,” Kargo CEO and founder Sam Lurye told VentureBeat. These digital twins provide the ability to simulate different yard and dock configurations to find the most efficient, effective way of moving materials in and out of a facility. For example, effectively simulating different trailer positioning in the yard and prioritizing the loading and unloading sequences based on where the material will go in the warehouse increases efficiency and decreases the idle time for truckers.

Transportation-as-a-service business models

Transportation companies are exploring new as-a-service business models that use digital twins to assess the cost of different offerings, said Jim Poole, VP of business development at Equinix. For example, rail authorities typically buy trains, spares, maintenance contracts and other necessary transport equipment from a train manufacturer. In an as-a-service scenario, the train manufacturer sells a service, like rail freight transport, where they are paid based on the reliability of the trains rather than the equipment itself. “This will only work if the train manufacturer can both model their equipment and integrate real-time performance data collected from the sensor on the train,” Poole said.

Managing configuration and performance of trucks, planes and trains

Jason Kasper, director of product marketing at Aras Corporation, said digital twins could also help tune the configurations of assets used for moving goods, such as trucks, planes and trains. Companies are starting to improve the performance of these assets by collecting sensor information, running simulations and analyzing the data to assess failure modes, timings and the resulting business impact. Kasper argues that including the configuration data is critical in understanding the effects that subtle differences between trucks could have on cost and performance. “If you think of the digital twin configuration first as the foundation and develop the right processes and methods to keep it up to date, you achieve more accurate decision-making, leading to better supply chain forecasting, reduced delays, improved maintenance decision-making and increased uptime of critical assets,” Kasper said.

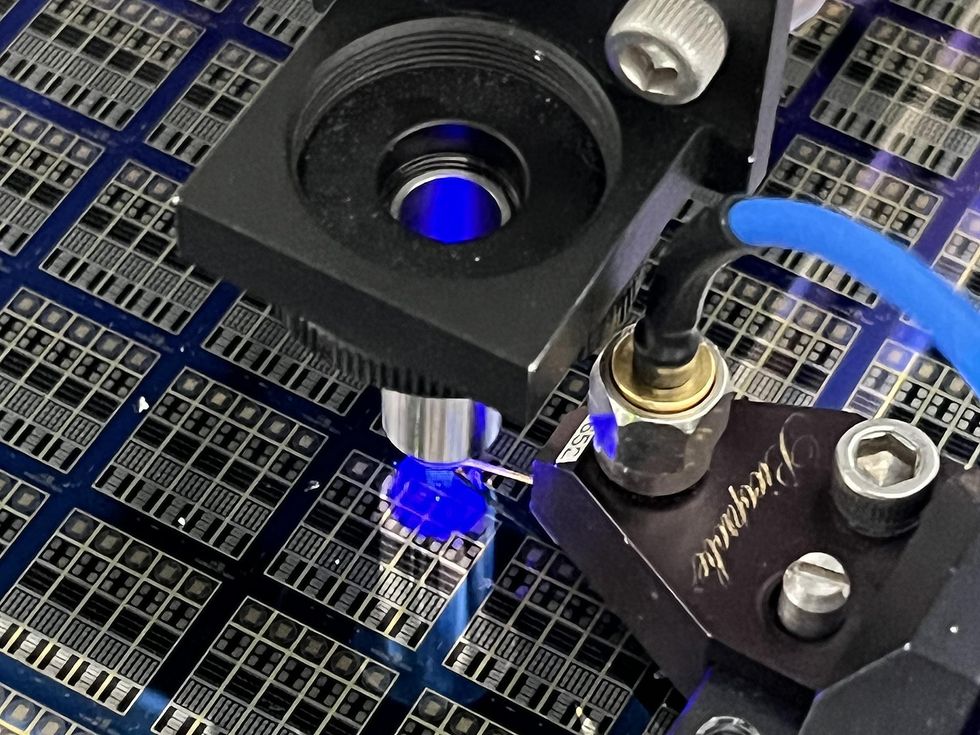

Integrated demand and supply planning

Blue Yonder customers, such as Micron Technology, a global leader in semiconductor memory solutions and the fourth-largest semiconductor company in the world, have created digital twins representing their end-to-end physical supply chain in detailed software models. These models capture semiconductor device manufacturing and distribution details across front-end wafer fabs and back-end assembly and test facilities. Scenario planning allows Micron to simulate the behavior of the supply chain under different demand and supply conditions. For example, Micron can anticipate its ability to meet varying demand levels when manufacturing capacity is fully constrained or unconstrained across different stages of the manufacturing network. It can anticipate capacity shortages before the problem occurs and evaluate the impact of specific interventions in the digital world before introducing them to the physical world.

Visibility and orchestration

Digital twins can also provide real-time visibility and orchestration across different stages of the end-to-end supply chain for manufacturers and retailers alike. Technology such as Blue Yonder’s Control Tower allows companies to maintain a bird’s-eye view of their product inventory in motion – on airplanes, ocean liners and trucks – and on inventory at rest at manufacturing plants, distribution centers, warehouses and stores. In addition, companies can track sales orders and purchase orders across the supply network and anticipate potential problems related to late shipments. Puneet Saxena, corporate VP of global manufacturing at High Tech at Blue Yonder, told VentureBeat, “The pandemic and associated supply disruptions have placed an unprecedented burden on supply chain professionals who are finding it impossible to reliably keep track of products moving across the globe,” Saxena said.

Reducing environmental impact

Supply chain twins could also reduce environmental impact through better decisions, said Tamir Strauss, chief product and technology officer at digital freight forwarder Zencargo. For example, a digital twin could help determine when stock levels in warehouses seem sufficient for the next few weeks and recommend using ocean transportation for freight scheduled to be delivered by air. It would have to plot new pickup routes from the factories to ports instead of airports, track space availability on relevant ships and possibly even combine goods from additional manufacturers into one container to further reduce costs and environmental impact.

Improve sustainability

Digital twins can also help companies keep pace with increasing customer demand for more sustainable products. “World-class delivery companies find that optimal route planning gets customer packages delivered on time and reduces environmental pollution by condensing time on the road,” said Adrian Wood, strategy development for DELMIA at Dassault Systèmes. There is often a tradeoff and digital twins can help efficiently represent tradeoffs between environmental factors, efficiency and cost.

Greg Price, CEO and cofounder at Shipwell, told VentureBeat that digital twins can also enable shippers to simulate different routes or modes, allowing for a better understanding of the carbon footprint the different paths may generate. For example, routes can be simulated to avoid peak traffic times in urban areas or use a less popular route that provides for a smaller carbon footprint.

Creating a circular economy

The idea of a circular economy is that the waste of one plant becomes the input of another. But one major challenge is variability in raw materials. Waste does not always look the same. “Digital twins help plants adapt to this variability,” Feor Labs CEO and founder Berk Birand told VentureBeat. Engineers at the receiving end can use digital twins to figure out how to use what they have been given most efficiently without resorting to real-life testing.

“Without digital twins, there would be no circular economy,” he added.

Adapt to market changes

Energy companies are turning to digital twins to help assess the impact of new market dynamics. For example, BP’s oil & gas downstream business processes 1.7 million barrels of crude oil per day in eight oil refineries across the globe. BP adopted AVEVA Unified Supply Chain to run complex analyses quickly, meaning their analysts can better assess commercial risks and economic drivers as they arise with accurate, real-time data. Complex analysis that used to take almost eight hours is now done in under four minutes. BP’s process engineers can also communicate effectively with plant operators and those making maintenance decisions, mitigating risk and improving safety. “As a result, BP’s traders get to market earlier, plant operating decisions are communicated sooner and decisions are being made faster than ever,” said AVEVA’s Gulati.

Anticipatory intelligence

Stanley Black & Decker’s CTO, Mark Maybury, told VentureBeat that the company is starting to use digital twins to facilitate anticipatory intelligence, predictive analytics and prescriptive analytics. “We use digital tools to design products, assess associated bill of materials (BOM), their manufacturability and eventually, their sustainability digitally,” he said. One challenge is that the models the company uses for different products, human processes, factories and distribution centers are at different levels of abstraction and often in different languages. For example, it must go between product models stored in computer-aided design (CAD) tools, manufacturing recipes in computer numerical controlled (CNC) systems and workflows described in business process modeling notation. “These models can have differing levels of specificity, expressivity and accuracy,” Maybury said.

Fleet Routing

Gaurav Gupta, partner and global head of digital engineering with global technology research and advisory firm ISG, recently worked with a global logistics provider that used supply chain digital twins to optimize fleet routing and reduce its annual fuel consumption by about 10 million gallons, resulting in $400 million in cost savings. In another case, a global retailer used Google Earth Engine, satellite imagery and Google’s BigQuery cloud data warehouse to trace how sustainably sourced its palm oil is by quantifying the level of deforestation near production.

Identify bottlenecks

Software development teams have long had rich metrics for identifying where development processes get stuck. Advances in machine vision could also make it easier to reconstruct physical bottlenecks in a digital environment. Datagen is already starting to pull this kind of data into digital twins to model how humans perform various physical processes like packing boxes, assembling parts and moving pieces. “You can track productivity of people – who’s doing what and when and where the bottlenecks are,” said Gil Elbaz, cofounder and CEO of Datagen. These digital models allow managers to assess the tradeoffs between bringing in more staff, finding better equipment, or devising a better approach.

Stress test the warehouse

“One of the strongest use cases for a digital twin in the supply chain industry is to conduct a ‘virtual stress test,’” said Zach Gomez, senior director of global logistics business at Realtime Robotics. Companies have regularly been conducting stress tests of their facilities and operations to see if they are adequate for busy seasons. Some retail firms sell half of their annual volume during the peak holiday shopping months. That means everything from the technology to the processes and procedures must work as intended. But doing actual tests is a time-intensive and costly practice and people are not always up to the additional stress. Using a digital twin, the entire facility is simulated to help an organization review their planning, iron out any kinks and identify potential problems. Improvements and fixes can be made and then re-simulated until correct.

“This can dramatically cut down on the time and expense of running a real-world stress test, letting you simulate it until you perfect it,” Gomez said.

VentureBeat’s mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Learn more about membership.

[ad_2]

Source link